SAVES ENGINEERING

OUR SERVICES

Machining

We process various Alloy Steels (Carbon, Automat, Reclamation, Stainless), Aluminum, Brass, Titanium, Pig Casting materials with our suppliers with high precision, automation and machine park in accordance with customer expectations, and we carry out our shipments within the control of measurement methods in accordance with the requirements of technology. . On a sectoral basis, we can produce all ferrous and non-ferrous materials with 3,4,5,7,9 axis machines. We are capable of grinding and honing surfaces with dimensional accuracy and parts with high surface quality.

Gear Group

In the most appropriate time, we provide our customers with high quality and economical prices in order to meet customer satisfaction at the maximum level.

Tattoo

Our forging companies, approved by the Aviation and Automotive Industries, can produce forged parts in various sizes and shapes, weighing 1 kg - 200 kg, with its modern machinery. It provides customer-oriented service by constantly following the technology within the framework of a total quality approach for Railway and Wagon Parts, Automotive and Defense Industry Parts, Construction Machinery Parts, Agricultural Machinery and Tractor Parts, various industry branches and applications with our professional quality staff.

Laser-Plasma Cutting / Bending / Welding

We can offer laser cutting, plasma cutting, bending, welding, sandblasting, painting and assembly services as a whole. Thanks to our suppliers' advanced technology machinery, including 5-axis laser cutting machine, we realize projects of various qualities and capacities of many companies operating in the country and abroad.

Casting

We serve your needs with our experienced and qualified team, as well as our suppliers with modern facilities with ISO 9001 Quality System Certificate, ISO/TS 16946 Quality System Certificate and ISO 14001 Environment Certificate. Leveling, sandblasting, part washing, polishing, impregnation and heat treatment processes are applied after casting. Leakage test, penetrant (crack test), mechanical tests and raw material acceptance tests (Chemical Analysis, Sand Analysis and Hardness Measurement) are carried out successfully in the laboratory environment. We are able to provide one-piece casting service from 50 gr to 4000 kg, which is 100% leak-proof and resistant to 220 bar pressure.

heat treatment

We serve our domestic and foreign customers with atmosphere controlled furnaces, vacuum furnace, nitriding furnace, aluminum aging furnace, induction units.

Covering

Our suppliers operate in other sectors, especially in the Defense and Aerospace Industry, and have ISO 9001.2008 ISO 14001:2004, OHSAS 18001 and AS 9100 Rev D quality management system certificates.

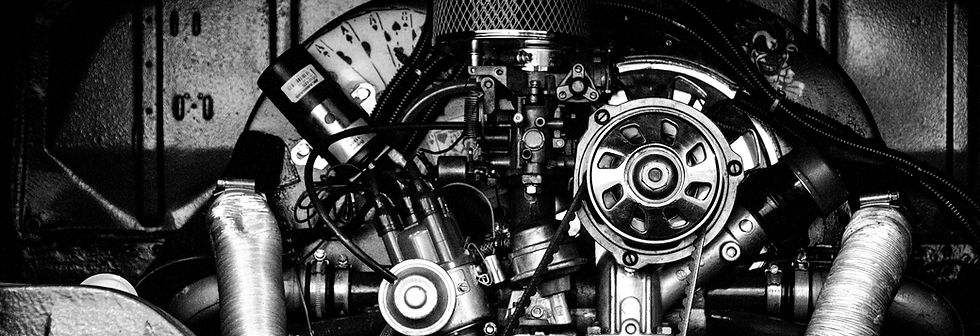

hydraulic systems

Our companies produce heavy machinery spare parts, tractor hydraulic steering pistons, tractor hydraulic middle arm pistons, concrete mixer trough pistons, automotive spare parts and industrial productions of our customers in accordance with their technical drawings and projects with machining and welded manufacturing methods.